Pitagora 4.0

LIFTs CONNECTED TO THE FUTURE

Passion powered by audacity

The Pitagora 4.0 controller represents the pinnacle of connectivity, safety and performance. It is the result of careful research and the right amount of audacity that takes you beyond the limits of the imagination.

State of the art

technology

Built-In

connectivity

Plug&Play

system

Advanced

features

Extended

product range

A smart, versatile, and flexible technology

An innovative electric system for lifts, inherently connected, capable of delivering unparalleled performance in both new and existing installations.

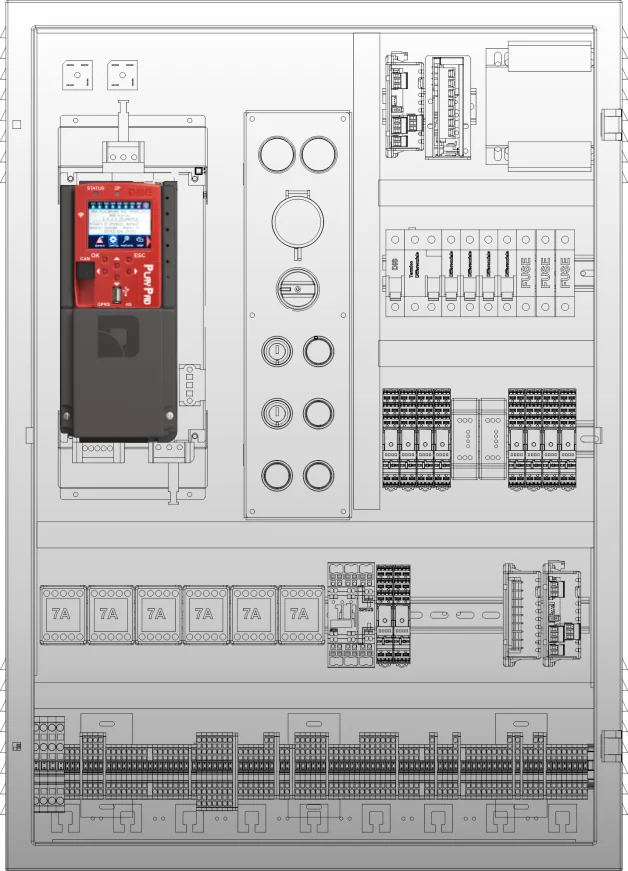

The electric heart

of elevators of the future

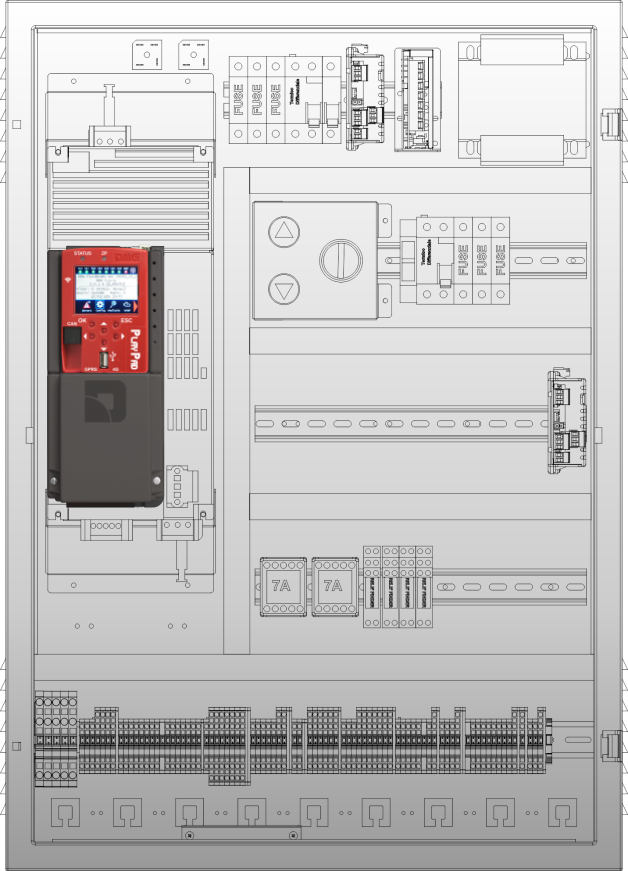

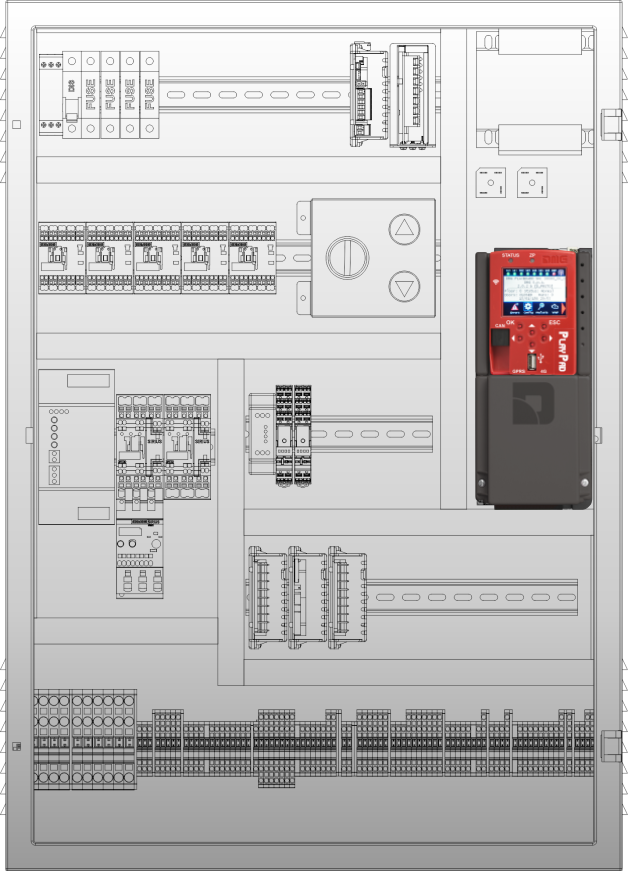

Pitagora 4.0 system is based on the unique and innovative combination of the controller motherboard and Fuji VVVF inverter, both integrated into a single, compact device. Users can access all the settings and the diagnostics either via the embedded PlayPad device or using the Fusion App for smartphones. With its robust hardware and advanced 32-bit software, Pitagora 4.0 is designed to meet and exceed the requirements of the EU Lift Directive and the EN81-20/50 Standard.

DMG Motherboard and Fuji LM2 VVVF

inverter integrated into a single device

- CAN BUS communication to cabin and floors

- WiFi connection

- 32-bit software

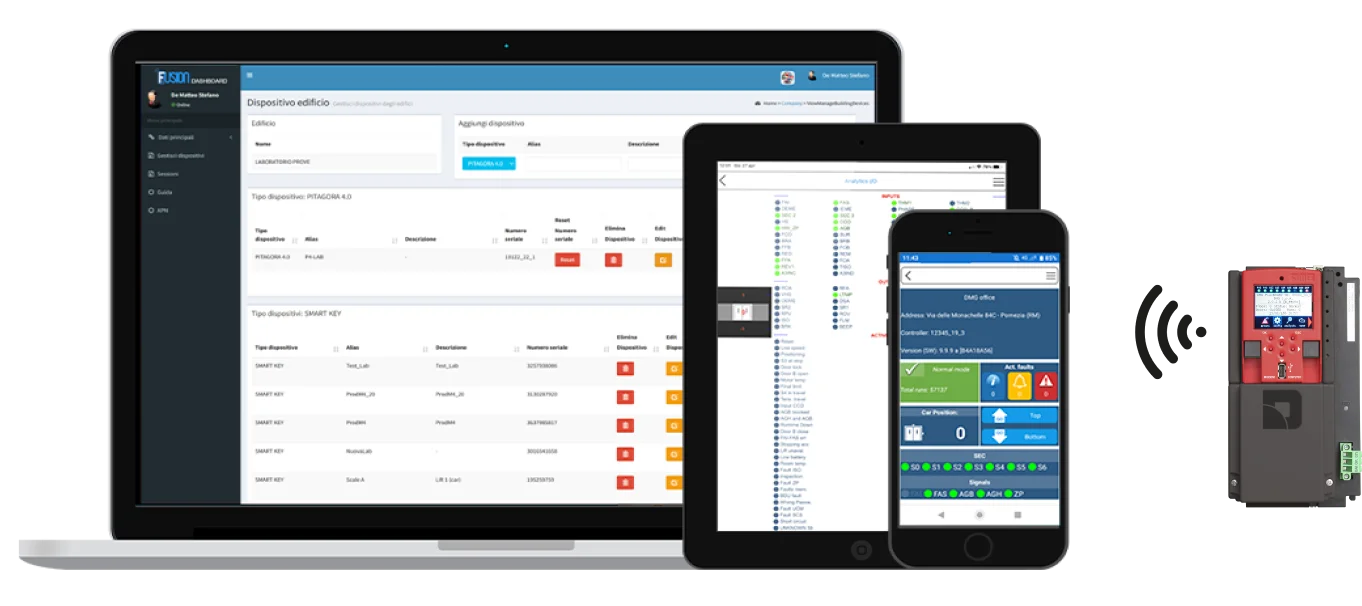

The future of lifts is online

Thanks to a smart network, you can monitor the elevator from anywhere you are, ensuring optimal management, reduced waiting times, and an unparalleled experience. Your ascent into the future begins here.

Fusion

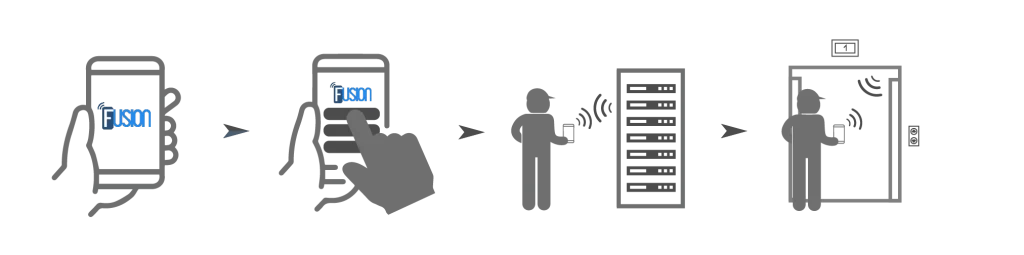

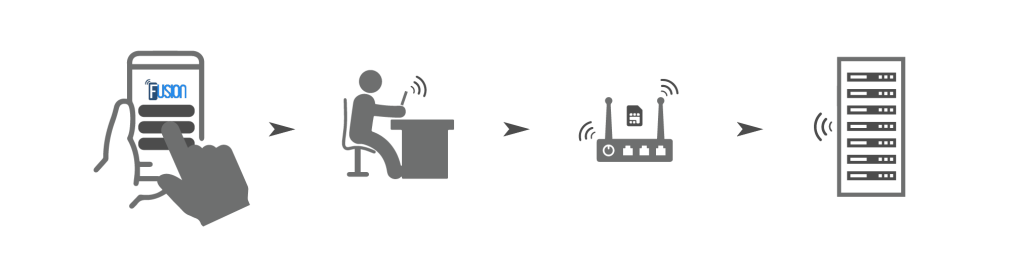

Fusion is DMG's cloud-based platform that enables remote, real-time monitoring of lifts equipped with Pitagora 4.0 connected electric system. Just download the Fusion App on your Smartphone or PC and start accessing your lifts in a fast and secure way. Fusion can also connect to the lift controller locally, using the WiFi interface

Maximizing performance through

preventive and predictive maintanance

The continuous processing of collected data and their comparison with the operational model enable the activation of early maintenance alerts, allowing the detection of issues before they occur. For example, sudden lateral micro-accelerations or interruptions in movement can early indicate the onset of more severe operational defects.

A connected electric system

Connectivity is inherent to Pitagora 4.0.

All controllers come standard with Wi-Fi connectivity, just like smartphones, at no extra cost.

To activate it, two solutions are available:

Locally (machine room / cabin / cabin roof)

Remote connection (via Telemaco II 4G modem)

Plug-and-play installation in record time

Innovation merges with ease, bringing the future of elevators to your fingertips. The Plug&Play system accelerates the entire process: connect, assemble, and experience a new level of riding comfort.

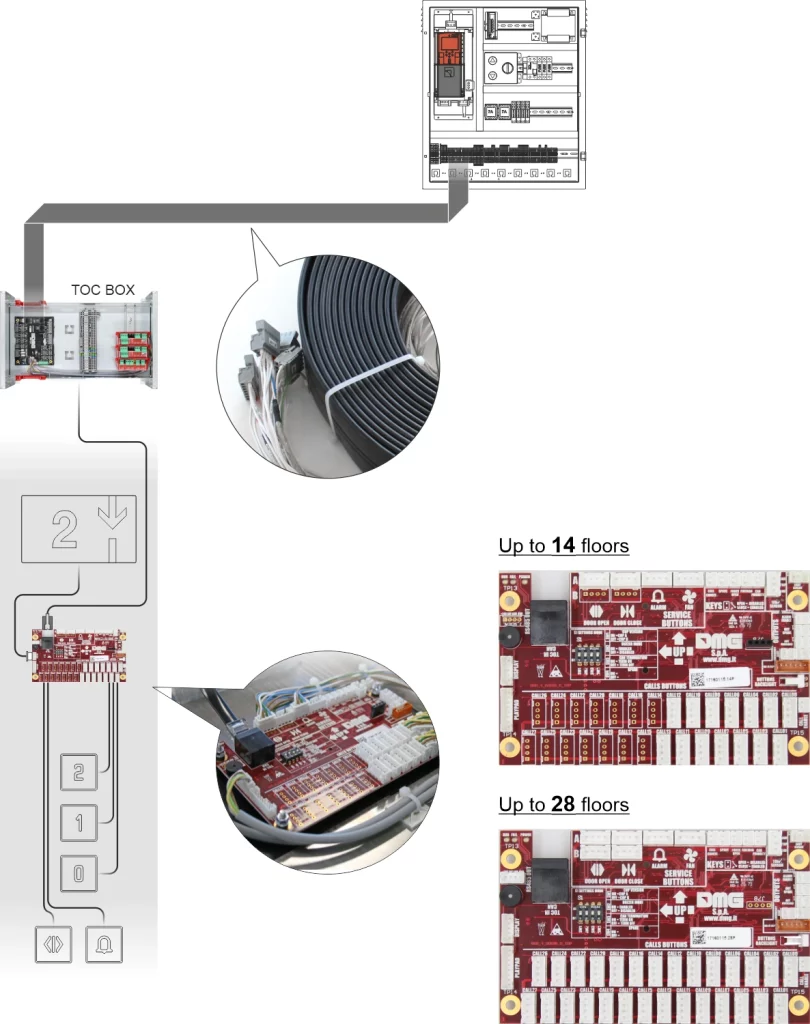

CAR CONNECTION

The lift car is connected to the Control Panel via a flexible 24-pole cable with twisted/shielded pairs for error-free data exchange. For higher shafts (> 55 m) a reinforced version of travelling cable is used.

For lifts up to 14 floors, standard cables between BDUs and the standard COP14 Cabin Interface Board are provided. When more than 14 floors are served, the COP28 interface board in the cabin panel is needed.

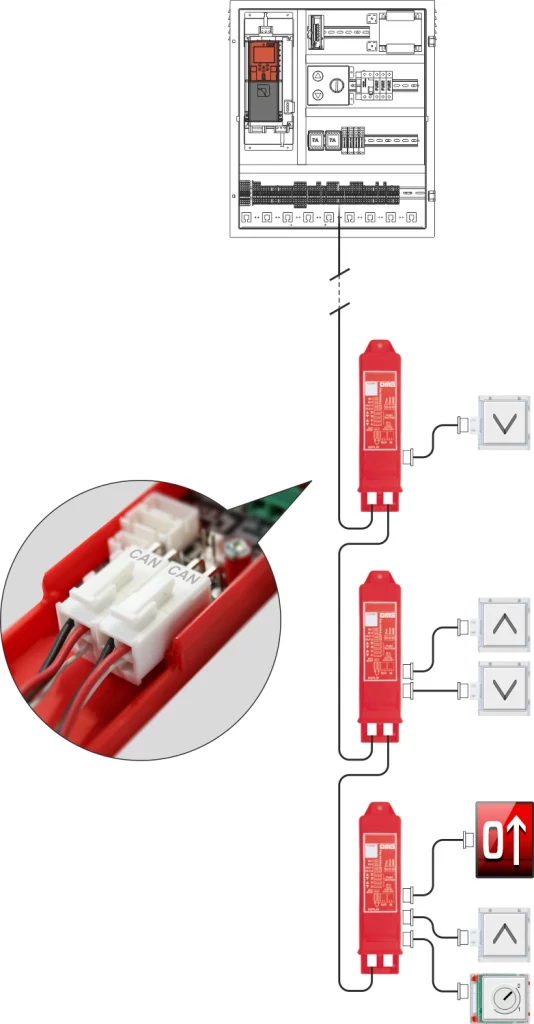

LANDINGS

serial wiring

Serial floor interfaces (BDU) connect the LOP elements (call buttons, indicators, key switches) with additional inputs for key switches, fire detectors, etc. The BDU interfaces are connected using 4-pole cables and mini-fit connectors. For lifts up to 14 floors, standard cables are provided. Installations with more than 14 floors served are provided with reinforced cables to prevent problems due to the voltage drops.

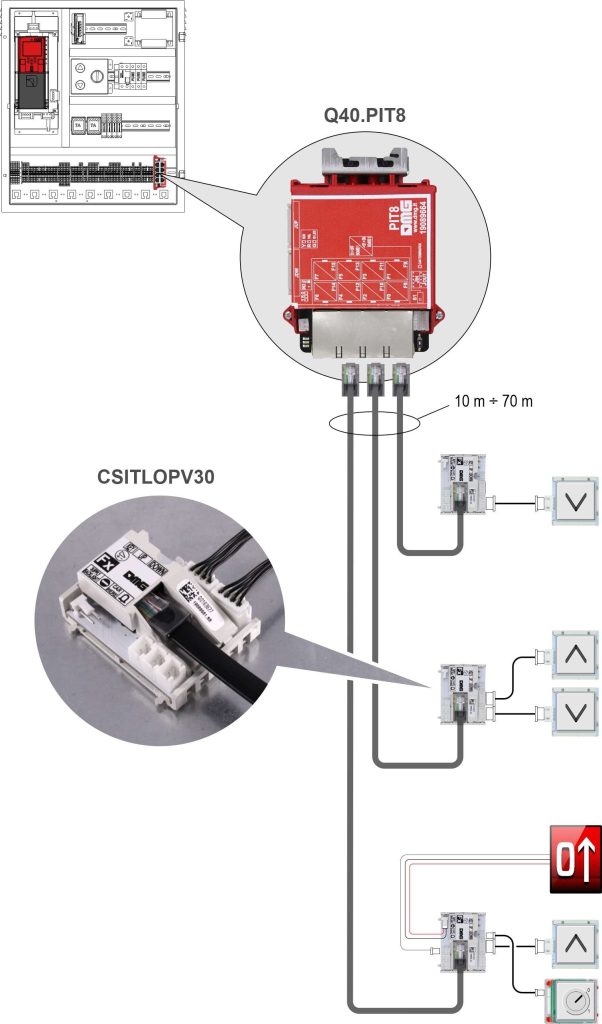

LANDINGS

parallel wiring

In parallel connected installations every landing panel is singularly and physically connected to the control panel. A dedicated interface is provided behind every LOP for easy wiring of all pushbuttons, indicators, and key-contacts. Through an electronic board on DIN guide, the controller can manage up to 8 access interfaces. 8-pole RJ45 ethernet cables connect the controllers to each LOP interface. For MODERNIZATIONS where the existing LOPs are kept in operation, all floors are equipped with a screw-terminals interface, which will connect them in parallel to the controller’s board.

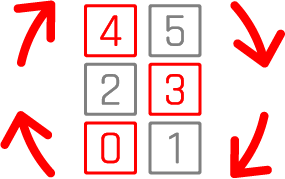

GROUPS

of elevators

From the simplest single installation to groups of elevators, PITAGORA 4.0 is the right product. Our controller can brilliantly manage up to 6 elevators in a group. Speed up to 4m/s. In sophisticated elevator systems, different elevators can be programmed for specific functions - such as servicing only particular floors or operating at different speeds. This can enhance the user experience by reducing unnecessary stops and optimizing travel times. Modern grouped elevator systems can optimize their routes and loads based on real-time usage data, which helps in reducing energy consumption or reducing time of travel. Some systems are capable of redistributing energy; for example, one elevator might generate energy through braking which can then be used to power another elevator in the system.

ABSOLUTE ENCODER

ABSOLUTE ENCODER

The ELGO-safe "ABSOLUTE ENCODER" is the best car positioning solution for more demanding applications. It adopts a magnetic band to accurately measure the position and speed of the car in the shaft.

As a certified safety device, integrated into the Pitagora 4.0 system, the Absolute Encoder also eliminates the need for all conventional electromechanical devices in the shaft.

INCREMENTAL ENCODER

INCREMENTAL ENCODER

A simpler and cost-effective alternative to the absolute encoder is represented by the "DMG INCREMENTAL ENCODER".

In its newest version, this device is based on a combination of cable and pulleys installed in the shaft and a magnetic reader designed to precisely detect the position and speed of the car with a resolution of 1.25 mm.

TRADITIONAL MAGNETIC SYSTEM

TRADITIONAL MAGNETIC SYSTEM

Only available for simpler installations with speeds up to 1 m/s, this conventional system to detect car position is fundamentally based on magnetic detectors positioned on the top of the car and a set of magnets at each floor.

MOTOR ENCODER

MOTOR ENCODER

This is the built-in solution for the car positioning system whenever a gearless machine is present in the installation. Like in the case of the DMG rope-and-pulley encoder, top/bottom magnetic limit switches provide the reset signal. This solution cannot be used in conjuction with the DMG UCMP system.

Toc Box

top of car

The Pitagora 4.0 Top-of-Car box is designed to match all requirements of EN81.20/50 code. It includes the remote inspection box and cables to main devices installed on the top of the car (door operator, etc.).Inside the box, the TOC board manages the serial communication between the controller and all the devices installed in the car.

Many functions, one single journey

Pitagora 4.0's software includes numerous features designed to make elevator usage even easier for users and enhance perceived safety.

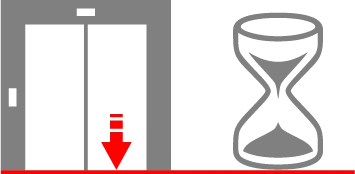

AUTOMATIC RETURN TO FLOOR

AUTOMATIC RETURN TO FLOOR

The controller can be programmed to automatically take the car to a pre-set floor after a period of inactivity, thus optimizing passenger waiting times at the busiest floor.

TIME ZONING

TIME ZONING

Same as the AUTOMATIC RETURN TO FLOOR function, but with the possibility of programming up to four daily time slots in which to move the lift to the selected floor. This feature is particularly suitable for high-traffic duplex/multiplex systems to reduce waiting times and increase efficiency.

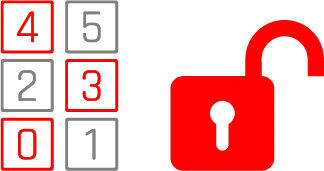

CODE-PROTECTED FLOORS

CODE-PROTECTED FLOORS

This function allows the creation of a custom code. Calls to protected floors will be enabled only after the custom code is entered using the buttons in the car panel.

ANTINUISANCE

ANTINUISANCE

This function is designed to counteract small acts of vandalism in lifts. It allows you to set the number of stops at floors without passengerd entering or leaving the car. Beyond this number, all remaining calls are considered nuisanc ecalls and are therefore canceled

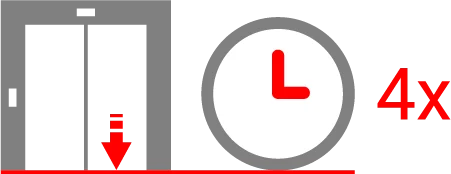

STAY-AT-FLOOR

STAY-AT-FLOOR

By pressing a combination of buttons on the car button panel ([FLOOR BUTTON] + 3x [DOOR OPEN]), the lift can be programmed to stop at the current floor for 5 minutes, preventing calls from other floors. It therefore facilitates loading and unloading operations, for example during a move. The function is instantly canceled by making any car call.

DOOR PRE-OPENING

DOOR PRE-OPENING

It is possible to set the car doors to open just before the lift has fully stopped at a floor, speeding up and optimising lift waiting times (in some cases, a safety circuit and UCM protection is required).

PENTHOUSE + GUEST

PENTHOUSE + GUEST

Enjoy greater security and privacy with direct access to your private apartment or penthouse. This optional feature can be used to temporarily enable a car call button, normally protected by a key, allowing your guests to reach you directly using the lift.

LIVE+, VIDEO SURVEILLANCE SYSTEM

LIVE+, VIDEO SURVEILLANCE SYSTEM

LIVE+ is a simple yet effective video surveillance system, fully integrated into your Pitagora 4.0. It allows passengers to monitor one or more "at risk" exit floors (e.g. the exit to the garage or street level) directly via the in-car Matisse display. The doors only open based on express consent from the passenger using the door open button.

AUTOMATIC EMERGENCY OPERATION

AUTOMATIC EMERGENCY OPERATION

In the event of a power outage, the lift is re-powered via a UPS system to take the car to the nearest (or predetermined) floor and open the doors, allowing passengers to evacuate. A simpler system is also available for gearless traction elevators: the brakes are opened in a controlled way to gently bring the car to the nearest floor by gravity and open the doors.

FIRE EVACUATION

FIRE EVACUATION

In case of fire, this function offers two different evacuation options: single floor or multi floor. Single-floor evacuation: The lift returns to a designated floor. Multi-floor evacuation: Multiple fire evacuation floors can be programmed in cascade. If one is not available because of a fire alarm, the next one becomes the destination.

FLOOR PRIORITY

FLOOR PRIORITY

This key-secured function allows taking control of the lift cabin by giving priority to car calls while all landing calls are disabled. This is vital for lifts located in special buildings such as hospitals.

ENERGY SAVING

ENERGY SAVING

When idle for a prolonged period, the PITAGORA 4.0 controller progressively enters "sleep" and "deep sleep" mode, turning off the car lights, the VVVF inverter, the position indicators and other devices. In this way the energy consumed during stand-by (when typically the lift absorbs up to 90% of the total consumption) is optimized.

TESTS AND MEASUREMENTS

TESTS AND MEASUREMENTS

A series of functions developed to verify that the main system devices are correctly installed:

- UCM test

- limit switch test

- relevelling test

- safety chain test

- door/floor contact test.

AUTOMATIC CALL TEST

AUTOMATIC CALL TEST

This function allows your maintenance technicians to streamline and optimize their interventions on the system, carrying out automatic call tests without the technician actually being present. These tests are feasible both with the system in service and excluding the doors.

PROHIBITED FLOORS

PROHIBITED FLOORS

When you need to exclude access to one or more floors, you can enable this function remotely or on site.

LIFT OFF FUNCTION

LIFT OFF FUNCTION

Via a button on the external button panel, this function can call the car to a preset floor, putting the system in OUT-OF-SERVICE mode; the lift can be reactivated and put back into operation using the same simple process.

A solution for every need

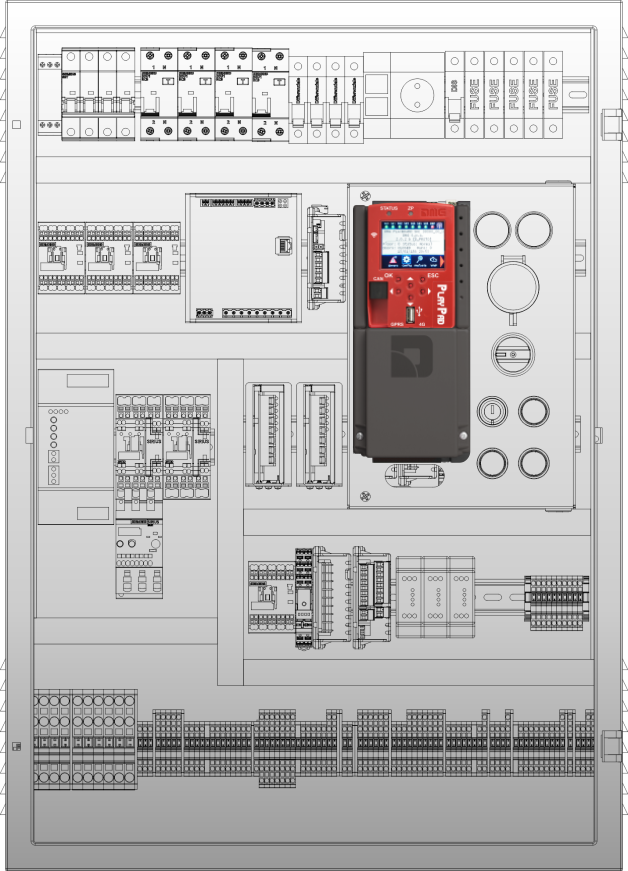

MR Gearless

- 4-7,5 kW(600×840×280 mm)

- 11-22 kW(600×1040×280 mm)

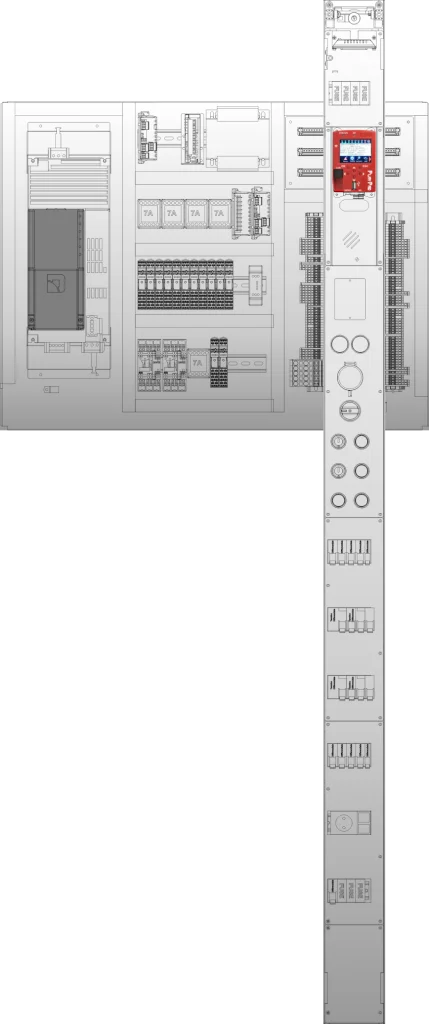

MRL All in One

(Single cabinet at floor)

- 4-15 kW(390×2000×230 mm)

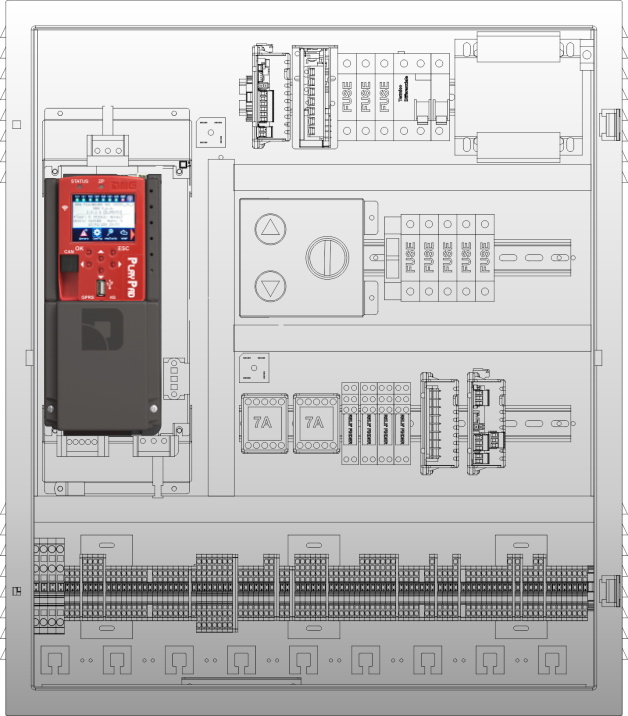

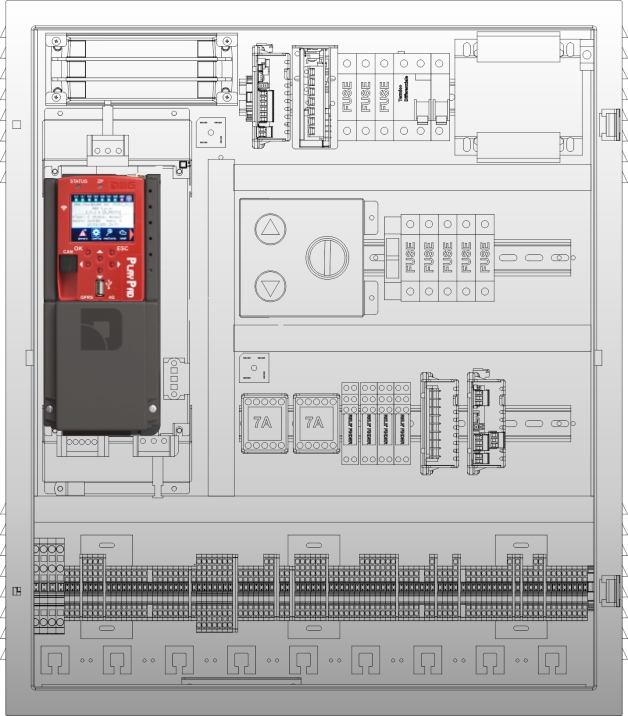

MRL STAR

Power unit in the shaft

+ Service panel at floor

- 4-22 kW(840×650×280 mm120×2000×110 mm)

HYDRO

- ≤ 38A/3 wires(600×840×280 mm)

- ≤ 60A/6 wires(600×840×280 mm)

- ≤ 99A/6 wires(600×1040×280 mm)

MR Geared

- 4-11 kW(600×690×280 mm)

- 15 kW(600×840×280 mm)

MR Geared

- 4-7,5 kW(600×690×280 mm)

- 11-15 kW(600×840×280 mm)

- 18,5-22 kW(600×1040×280 mm)

MR Gearless

Power unit in the shaft

+ Service panel at floor

- 4-7,5 kW(600×690×280 mm)

- 11-15 kW(600×840×280 mm)

- 18,5-22 kW(600×1040×280 mm)

HYDRO

- ≤ 38A/3 wires(600×840×280 mm)

- ≤ 60A/6 wires(600×840×280 mm)

- ≤ 99A/6 wires(600×1040×280 mm)

Tools

FORM

SUPPORT